Pipe Eating is a form of pipeline replacement that more or less completely removes the old pipe from the ground, leaving no shards or waste material behind.

Often this technique is used to replace clay or concrete pipelines. Usually to achieve a pipe eating replacement a Microtunnelling machine is used that is set up to follow the line and grade of the existing pipeline.

As the Microtunnelling machine advances it cuts out the old pipe together with any of the surrounding ground that is being removed to create a void of sufficient size to accept the replacement pipe.

The new pipe is jacked in behind the Microtunnelling machine and is used to move it forward through the ground.

Once the Microtunnelling machine arrives at the target pit it is removed together with any temporary works that had been used to support the installation works to leave the new pipe in position ready for incorporation into the pipeline network.

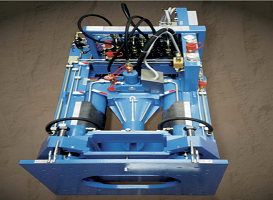

Pipe Reaming is another form of pipeline replacement that more or less completely removes the old pipe from the ground, leaving no shards or waste material behind. In this case a horizontal directional drilling rig is used to achieve the pipeline replacement (suggest link here to HDD section). The drilling rig advances its drill rods through the existing pipeline until it reaches the target access point. A reaming head is attached to the drill rods with the new pipeline fixed to it via a swivel.

The replacement pipe can be polyethylene, ductile iron or steel. As the drill rods are pulled back the reaming head destroys the existing pipe. The fragments together with any of the surrounding ground that is being cut out to create a bore of sufficient size to accept the replacement pipe are removed using the drilling fluid. Once the reamer reaches the launch access, it is removed, and the new pipe is then available for connection to the pipeline network.

The advantage of this technique is that if a very significant upsize is required, a preliminary reaming run can be made to remove the old pipe followed by as many further reaming runs that may be required to upsize the bore to the required size to accept the new pipe. Drilling fluid can be utilised to maintain the expanded bore between reaming runs.

When very large upsizing is required consideration needs to be given to other existing services that are in close proximity to the bore route to avoid any potential damage or loss of service.